Human-Machine-Interfaces (HMIs) are dashboards that act as an interface between a user and a machine or device. They are designed to present information in a graphical format about the status of a process to an operator. HMIs can be password protected to only give authorisation and access to operators with the correct security clearance. However, a growing and recurring problem has been the loss or misplacement of these critical passwords, causing a host of delays.

Machine and plant operations are busy, sometimes chaotic places. With the best of intentions some of us misplace or fail to keep a record of these all-important passwords and become reliant on suppliers to send through reminders, often at inconvenient times. And according to one partner, CT Systems, a total solutions systems integrator, these requests would come in at all hours which, of course, isn’t great for the supplier nor the businesses that needed them.

A better, more efficient, solution would eliminate the need for passwords yet still provide the necessary layers of security i.e. an HMI with personalised authorisation.

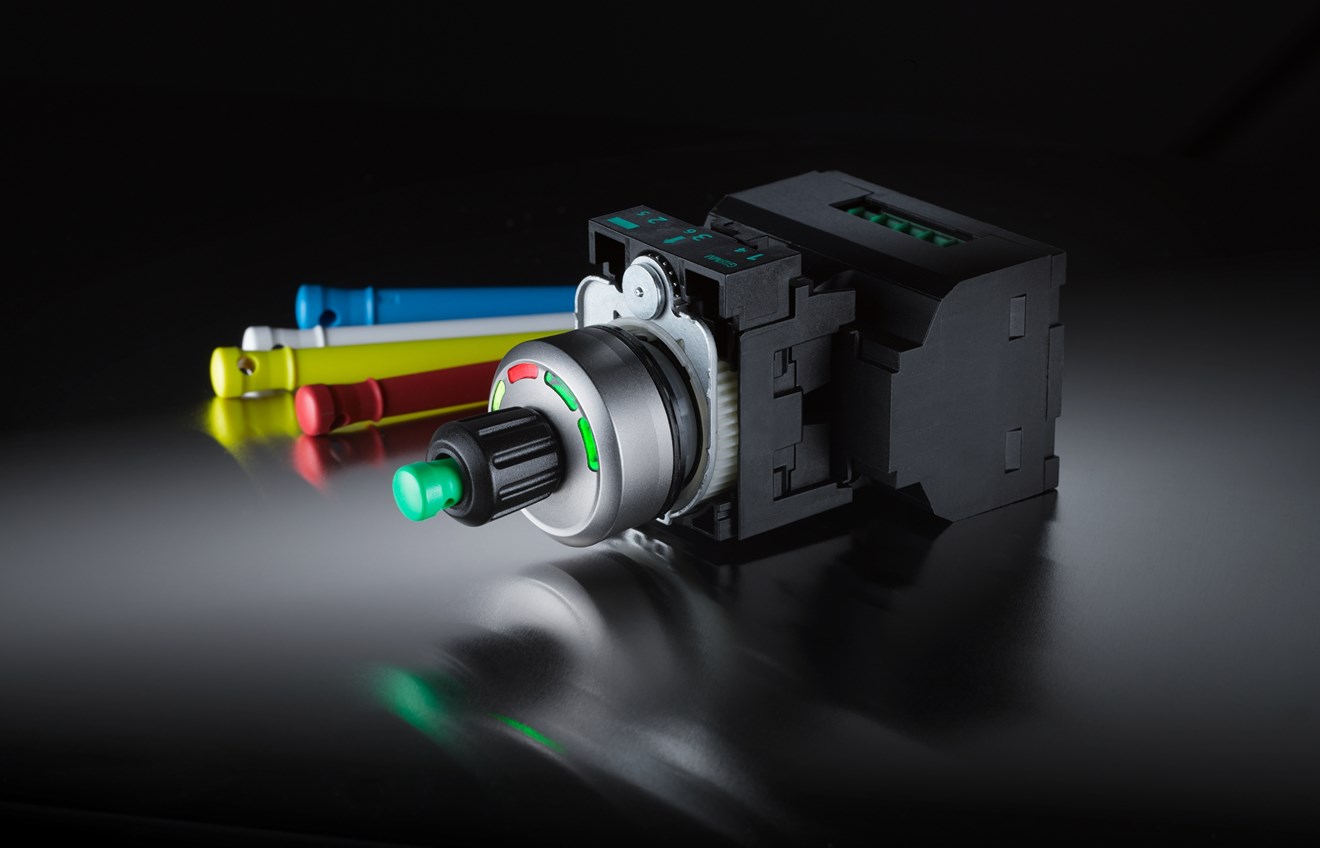

ID key-operated switches

ID key-operated switches use electronic locks instead of conventional mechanical locks. The switches feature a level of customisation that allows the user to set authorisation for machine access, and the associated keys have a radio-frequency identification (RFID) chip that makes them uniquely identifiable. The key and switch are connected by a stable radio link and do not come into contact with the HMI.

ID key-operated switches are designed to deliver a level of flexibility through four digital outputs that can be freely assigned and used successfully for control purposes. Varying levels of authorisation are represented by separate – and different coloured – keys. The option of an additional key that can be configured entirely to a user’s specifications would give additional flexibility.

Depending upon the application different ID key-operated switches can be deployed. One could be used autonomously, providing access for all users while a second could be used to communicate with a controller via an IO-Link, the industrial communications networking standard used for connecting digital sensors and actuators. The IO-Link allows registration and precise allocation of authorisation levels.

As well as flexibility and customisation the switches offer a level of security and usability that can’t be matched by any password solution. If the ID key is lost, systems remain secure as the key is simply blocked and replaced, while any individual access levels act as a time stamp to catalogue who last used the HMI and at what time – offering additional security. In addition, it is also possible to detect when a key has been inserted on the PLC (programmable logic controller) side via a monitored output.

From a safety and quality perspective, operation, downtime and maintenance information can be recorded with the aid of a database.

Although the use of ID key-operated switches is still relatively new, the potential of these devices opens up options for other applications i.e. in PLCs it could be used for other functions like switching-on specific features.

A forgotten password could easily grind your operation to a shuddering halt – don’t let that embarrassment happen to you.

By Martin Brown, product manager Siemens