Siemens has been selected by Lancashire based Hoofcount Ltd., the revolutionary manufacturer of market-leading footbaths for cows, to provide critical data-gathering capabilities that will have a significant impact on animal health and welfare, helping farmers to become more operationally efficient.

Siemens’ data capture and control technologies are helping farmers make informed decisions to better tackle lameness, a major problem in dairy herds.

Hoofcount is utilising Siemens’ expertise in combining the real and digital worlds using LOGO, an intelligent logic module for small automation projects in industrial settings. LOGO manages the control of the key mechanisms of Hoofcount's footbaths, such as chemical and water pumps, and animal feed controls.

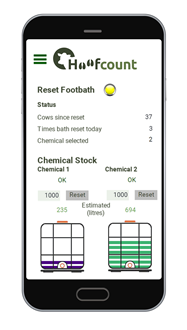

LOGO controllers allow Hoofcount to track the cows that go through its footbaths and provide valuable data on the herd, which can then be displayed on an HMI screen for visualisation. The baths can be controlled remotely and have the capability to feed data up to the cloud for analytics.

Lameness is caused by bacteria picked up on the hoof which leads to restricted mobility, pain and behavioural changes. These impacts, including animal suffering, increased CO2 footprint, loss of milk production, decreased fertility, increased treatment, increased trimming costs and unnecessary labour, are estimated to cost several thousands of pounds per year for a 100-cow herd. While across the UK dairy industry, the financial impact of lameness is estimated to be well in excess of £100 million.

These impacts are a major focus for the whole food and beverage sector’s supply chain. But regular foot baths for cows help to reduce and prevent hoof illness and lameness.

“When we first introduced footbaths in the UK in 2012, we were already ahead of the game because they were quite new,” said Anthony Marsh, Dairy Engineer and Founder of Hoofcount Ltd. “But, with the rapid advancements in technology, we’ve reached a point where we need to go that extra mile and be revolutionary again. And, to keep leading the way, we needed that input and expertise from Siemens.

“Working with Siemens has given us a thrust for producing the technologically advanced Hoofcount. Simply put, we have transformed our footbath into a pioneering piece of equipment that will eventually help cattle farmers in making data-driven decisions.”

With its humble beginnings as a small family firm in rural Lancashire and a deep understanding of farmers’ and their animals’ needs, Hoofcount has developed its range of automated footbaths suitable for every farm.

Every Hoofcount footbath is designed, folded and built in its continuously growing workshops in Lancashire, with the company producing around 300 footbaths a year.

The footbaths are optimised to reduce water and chemical usage, thereby reducing overall operational costs. They are easy to maintain and have a built-in cleaning system which takes under 3 minutes using two chemical pumps after the set number of cows have passed through.

Hoofcount’s simple Smart Controller allows users to monitor and change settings from a mobile device, as well as receive important notifications. With the standard footbath being perfect for herds of up to 200 cows, they have also been specially designed to work with robot systems such as the Excel footbath, which is for farms with larger herd numbers.

Hoofcount’s footbath production has more than doubled each year, enabling the company and its business to also grow twice as much. Its footbath cycle has been proven to keep cattle healthy, improve herd feet, reduce the loss of milk production and increase fertility. Accordingly, data from its customers has shown that using the footbaths has seen a reduction in lameness, as well as a financial saving of up to £8000 per 100 cows per year.

And, as a growing family business, Hoofcount prides itself on supporting farmers across the world. Accordingly, Hoofcount footbaths are now being shipped to over 16 countries across the world including Canada, Germany, Sweden and the Czech Republic.

“Creating closer ties to the agriculture industry and bringing the latest technology that can transform the welfare of farm animals – a crucial factor in running healthy farms – makes Siemens proud,” said Lee Fletcher, Business Development Manager, Siemens Digital Industries.

“Through Hoofcount’s close work with Siemens, its design philosophy has been underpinned by industrial learnings such as the use of open standards. The technologies used by Hoofcount are scalable and have the ability to be connected to IoT devices when the need arises. The possibilities are endless. Smart controls will allow farmers to monitor and control the footbath via an app, regardless of location.”

Anthony Marsh added, “Clearly, our partnership with Siemens enables us to be ideally positioned to move forward quickly and sustainably, and to scale the technologies as and when required with the assurance of benefiting from Siemens’ industrial expertise.

“Hoofcount is certainly well-positioned to continue market-leadership and assist cattle farmers grow their business whilst ensuring farm animals' health is a top priority.”