Sixty years since many of Britain’s railway lines and train stations were closed following the infamous Beeching Review, Siemens Mobility’s Chippenham factory will manufacture the innovative technology which will be at the heart of the soon-to-be re-opened Northumberland Line.

The award by Network Rail covers the signalling and control infrastructure that will transform the existing freight line into one serving both goods and passengers. The proven ‘modular plus’ technology which will be used has already transformed the everyday journeys for people in North Wales and will be transported directly to site saving time and cost of design, manufacture, assembly, test and installation.

MP for Chippenham, Michelle Donelan, said: “This Government has invested more in rail than any Government since the Victorian era, to connect businesses, people and our towns which is a key part of our levelling up agenda. I have submitted successful bids to the Restoring your Railway Fund for Corsham Station. the reopening of the Northumberland Line under this Government scheme also delivers for my constituents by supporting jobs at Siemens Mobility here in Chippenham who have been awarded the contract to provide pioneering technology for the new Northumberland line. This is great news for technology and innovation and Chippenham's economy.

Rob Morris, Managing Director, Rail Infrastructure for Siemens Mobility said: “The new Northumberland Line is a great example of levelling up in action. We are proud to help the Government and Network Rail roll-back the Beeching cuts to upgrade and reopen lines more quickly. This will provide better and more efficient transport links to improve the lives of people across the region.

“With more projects like this, and by using innovative technology, we can transform lines and passenger journeys up and down the country quickly and cost-effectively. Best of all the solution is designed and manufactured in Britain supporting local jobs and skills for the future.”

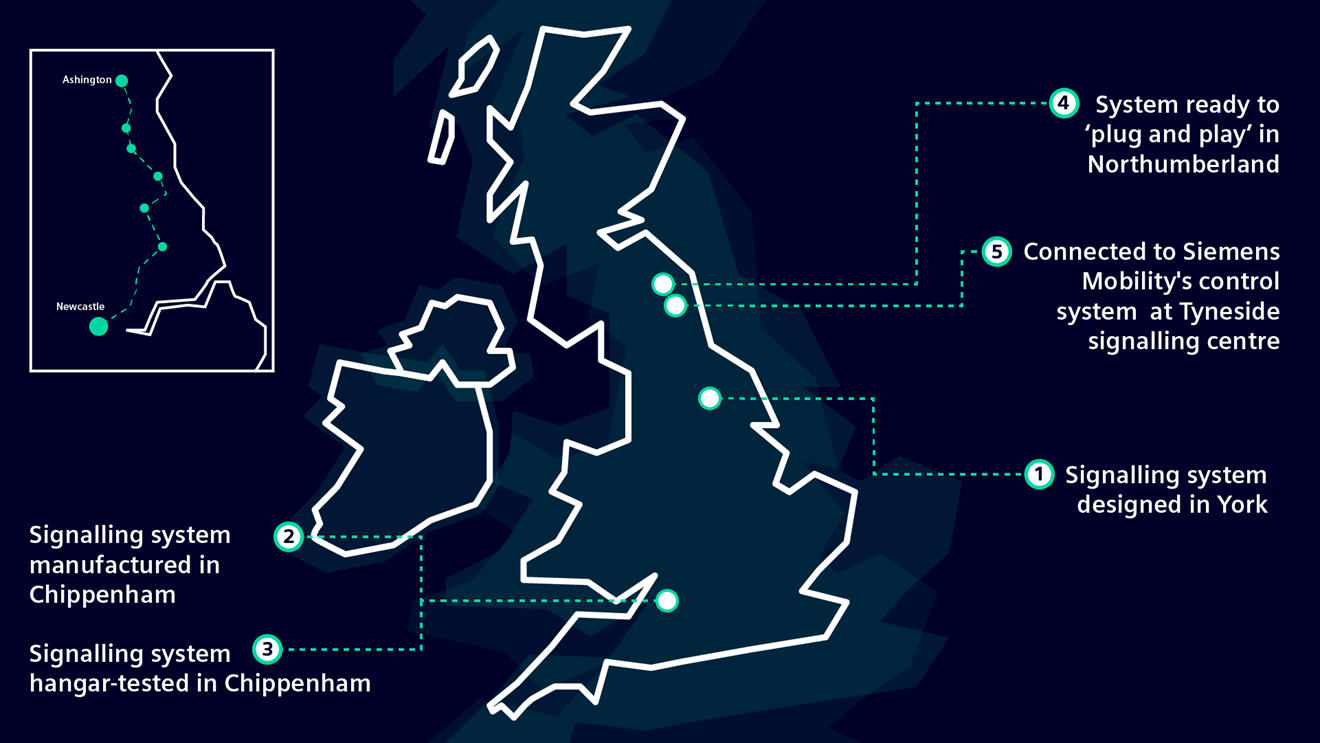

The Northumberland Line’s signalling system will be manufactured and tested by Siemens Mobility in Chippenham, Wiltshire, home to the UK’s only remaining dedicated signalling and control facility. It supports around 900 local manufacturing, research, engineering and support staff and, as well as serving the domestic market, exports around 25% of all equipment produced. The project will be managed and delivered from the company’s 200-strong York office.

Responsible for the design and delivery of all telecoms, lineside infrastructure and power upgrades, Siemens Mobility teams will also install or upgrade 8 level crossings (a mixture of CCTV and Obstacle Detection technologies) as well as new workstations at Tyneside IECC as part of the project.

By using digital, network-based technology, together with simple bases and lightweight structures, the embodied carbon in the scheme, and so the cost, will be significantly lower than conventional schemes, helping support the industry’s decarbonisation targets.

Six new stations are expected to be constructed to stimulate economic growth along the route, subject to planning permission. Towns such as Blythe and Ashington – birthplace of England’s football world cup winning brothers Jackie and Bobby Charlton and cricket world cup winner Mark Wood – will again be connected with Newcastle by rail, opening up new opportunities for sport, education, leisure and travel.